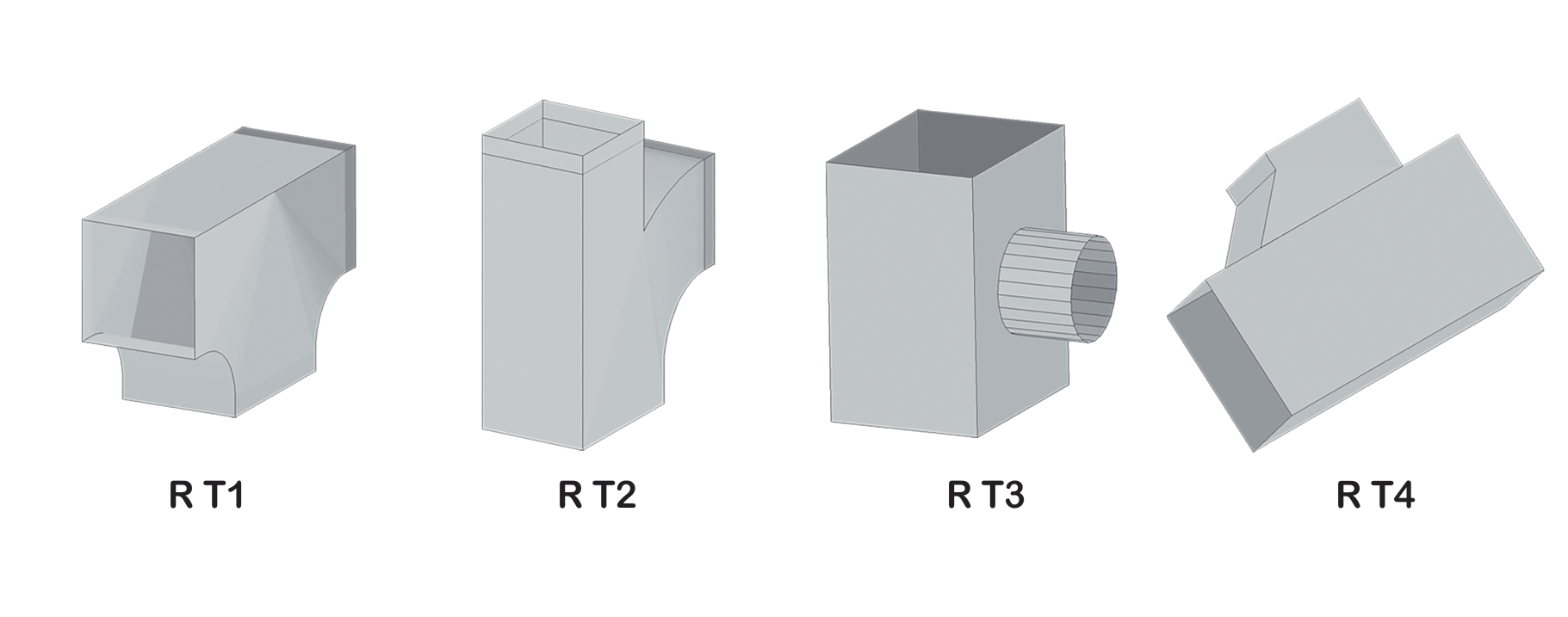

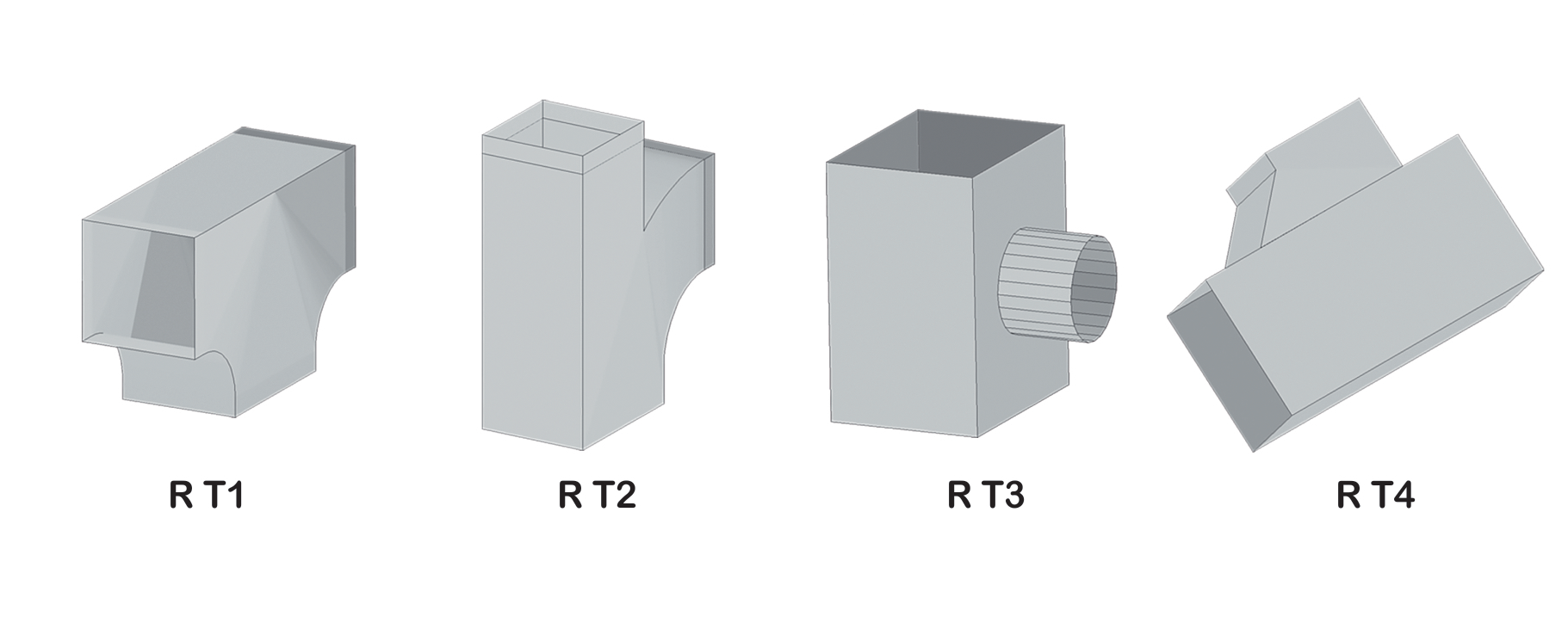

Tees

توضیحات

The tees of the rectangular duct system produced by Kian Fan Industrial Group, with precise design and robust structure, are an efficient solution for branching and dividing airflow into two paths in ventilation networks. These fittings, manufactured using galvanized sheet and the Pittsburgh seam technique by utilizing advanced machinery, feature reinforcing beads to increase strength. The connection of tees to other system components is made via TDC flanges and EPDM sealing tape, which guarantees excellent sealing and reduced air leakage. The appropriate aerodynamic design of this product minimizes pressure drop and airflow turbulence at the branch point, making it an ideal choice for commercial and industrial projects.

توضیحات تکمیلی

Introduction and Technical Structure

In the design and execution of rectangular ductwork networks, creating branches to distribute air to different parts of a building or machinery is inevitable. Kian Fan Industrial Production Group, by producing standard tees for the rectangular duct system, provides an engineering and precise solution for managing airflow division. The structure of these tees is completely similar to the main ducts and is made of high-quality galvanized sheets.

The production process of tees is carried out fully mechanically; after 3D modeling and precise cutting of the sheet by plasma machines, the bending stages are performed to create the geometric shape of the tee (usually with a 45-degree angle for the branch). The edges of the sheet are connected to each other using the Pittsburgh seam, which creates a strong and integral connection. To increase strength and prevent deformation of the tee due to air pressure, transverse reinforcing beads are created on the body surface. If necessary for high pressures, additional reinforcing rods can also be used.

Connection System and Features

The connection of tees to other components of the rectangular duct system, like the main ducts, is done using TDC (Transverse Duct Connector) flanges. This connection method includes flange profiles, corners, and cleats which accommodate the duct surface in a sliding manner. To guarantee complete sealing and prevent air leakage at the connection point, EPDM sealing tape is used between the flanges.

One of the important features of Kian Fan tees is their aerodynamic design. Dividing airflow can cause turbulence and pressure drop; however, the precise engineering of the branch angle and internal corners at Kian Fan ensures that airflow divides into two paths with minimal friction. This helps maintain system efficiency and reduce fan energy consumption.

Specialized Applications

Kian Fan rectangular tees have widespread applications in all projects that use rectangular ducts. In office and commercial buildings, these tees are used to divide airflow from the main duct into sub-branches serving different rooms or adjacent spaces. In factories and industries, this product is used to distribute air to multiple production lines or different machines.

Also, in central HVAC systems of hospitals and hotels where precise air distribution is required in different sections with varying pressures, tees with TDC connections and EPDM tape are an ideal choice. This product is also used in industrial exhaust systems to collect pollutants from multiple points and direct them to a main outlet.

Conclusion

The tees of Kian Fan Industrial Production Group, relying on precise machine production, standard TDC connections, and robust design, are a reliable solution for branching in rectangular duct systems. Choosing this product guarantees proper air distribution, reduced leakage, and increased ventilation system efficiency.