Flexible Sleeves

توضیحات

The flexible sleeves of the rectangular duct system produced by Kian Fan Industrial Group, with flexible design and robust structure, are an efficient solution for compensating for installation errors, thermal expansion and contraction, and absorbing vibrations in ventilation networks. These fittings, manufactured using galvanized sheet and the Pittsburgh seam technique by utilizing advanced machinery, facilitate the connection of ducts in cases where they are not exactly aligned. The connection of sleeves to other system components is made via TDC flanges and EPDM sealing tape, which guarantees excellent sealing and reduced air leakage. By creating flexibility in the duct path, this product prevents mechanical stress from being applied to the duct body and connections.

توضیحات تکمیلی

Introduction and Technical Structure

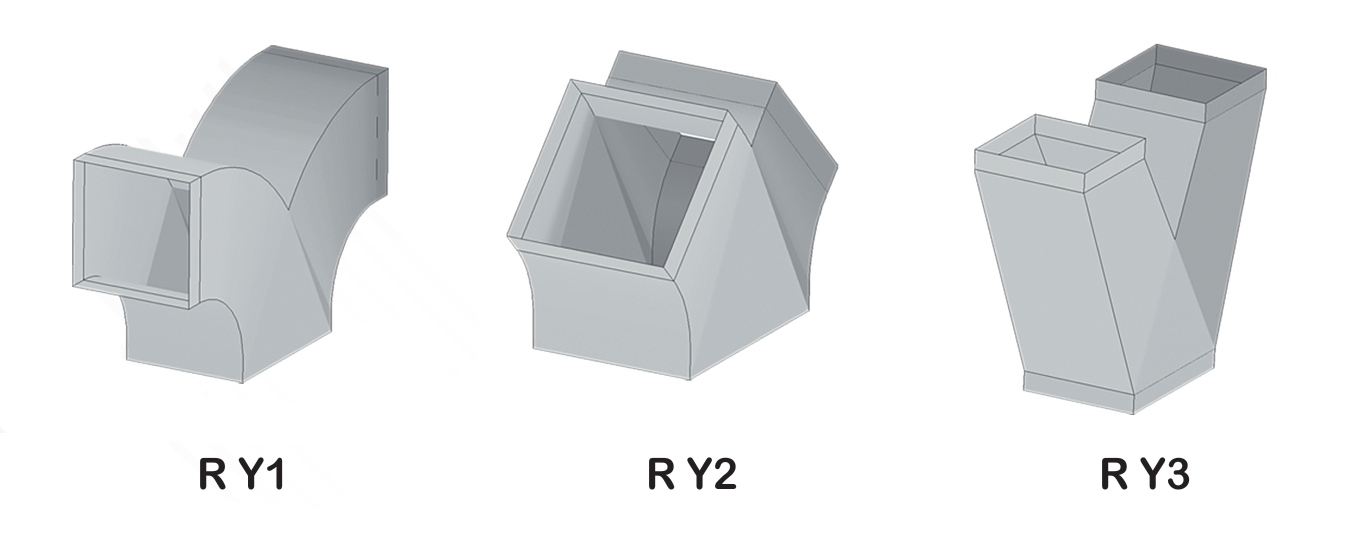

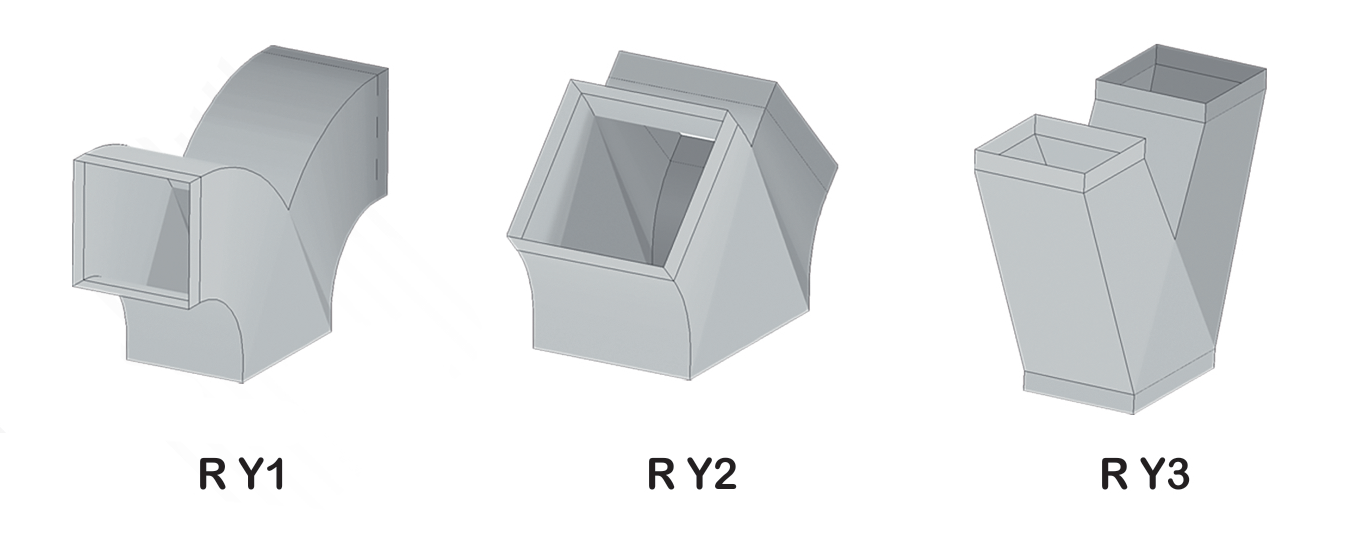

In the execution of rectangular ductwork systems, it is not always possible for the two ends of the duct to be precisely aligned, and field conditions may require minor changes in the path. Kian Fan Industrial Production Group, by producing standard flexible sleeves for the rectangular duct system, provides an engineering solution for creating flexibility at sensitive points in the network. The structure of these sleeves is made of high-quality galvanized sheets and is designed to allow for slight stretching, compression, or angle changes.

The production process of sleeves is carried out fully mechanically; after modeling and precise cutting of the sheet by plasma machines, the bending stages are performed to create a specific shape that allows for relative movement of the edges. The edges of the sheet are connected to each other using the Pittsburgh seam, which creates a strong and integral connection. To increase strength and prevent unwanted deformation, transverse reinforcing beads are created on the body surface.

Connection System and Features

The connection of sleeves to other components of the rectangular duct system, like other fittings, is done using TDC (Transverse Duct Connector) flanges. This connection method includes flange profiles, corners, and cleats which accommodate the duct surface in a sliding manner. To guarantee complete sealing and prevent air leakage at the connection point, EPDM sealing tape is used between the flanges.

The most important feature of Kian Fan sleeves is the ability to compensate for installation errors and thermal expansion. In long duct runs, temperature changes cause the metal to expand and contract, which can damage the duct body; the sleeve prevents stress and breakage by absorbing these longitudinal changes. Also, at the connection point of the duct to vibrating equipment such as fans, the sleeve acts as a vibration insulator, preventing the transmission of noise and vibration to the duct network.

Specialized Applications

Kian Fan rectangular sleeves have applications in various situations. In construction projects where the distance between two duct points may change due to building settlement or execution errors, the sleeve compensates for this difference. In factories and central facilities, installing a sleeve is essential for absorbing vibration and expansion at the inlet and outlet of Air Handling Units (AHUs) and large fans.

Also, in ductwork paths that pass through building expansion joints, sleeves are used to separate the duct movement from the structure. This product can also act as a disconnectable connection at points requiring periodic dismantling for service or repairs.

Conclusion

The flexible sleeves of Kian Fan Industrial Production Group, relying on precise machine production, standard TDC connections, and flexible design, are a reliable solution for managing stresses and longitudinal changes in rectangular duct systems. Choosing this product guarantees increased system lifespan, reduced noise, and ease of installation and maintenance.