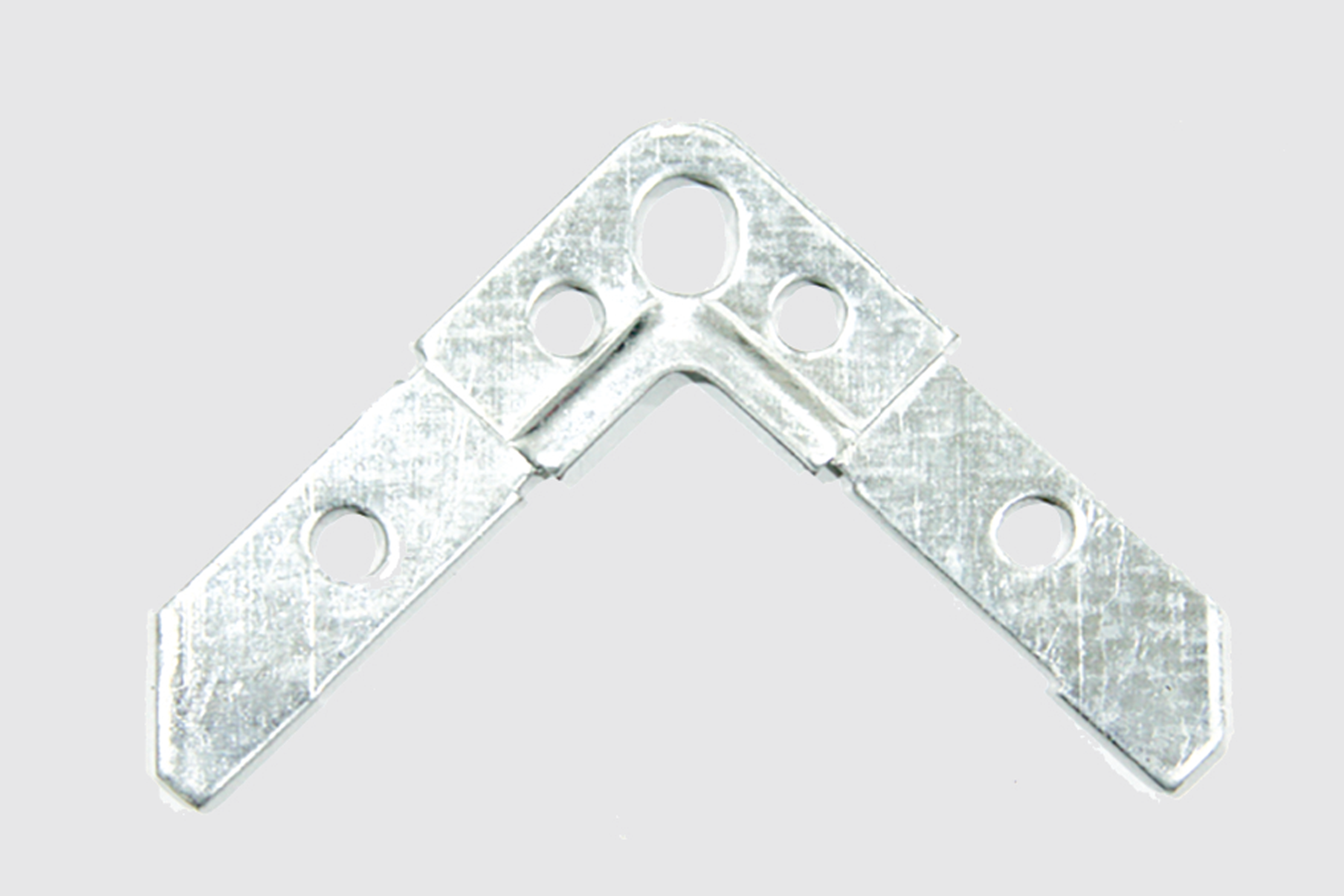

Corners for TDC Flanges

توضیحات

The TDC flange connection corners produced by Kian Fan Industrial Group are key, high-quality auxiliary components used for the strong and precise connection of flange profiles in rectangular duct systems. With standard design and robust structure, these corners are responsible for securing the flanges at the four corners of the duct and creating a surface for bolt and nut connections. Using these components alongside EPDM sealing tape provides a completely sealed and standard connection that resists positive and negative system pressures. The high precision in the manufacturing of these corners significantly increases the speed and quality of the ductwork assembly.

توضیحات تکمیلی

Introduction and Technical Structure

In the TDC (Transverse Duct Connector) flange system, which is a modern and efficient method for connecting rectangular ducts, auxiliary components play a fundamental role in guaranteeing strength and sealing. Kian Fan Industrial Production Group, by producing special corners for TDC flanges, has offered a complete complement to its connection system. These corners are typically made of galvanized sheet with appropriate thickness or corrosion-coated steel to ensure high durability in humid environments.

The structure of these corners is engineered to match precisely with the TDC profiles and cleats used. They are placed at the ends of the flange profiles and, using bolts and nuts, tightly secure two adjacent flanges together. This mechanism ensures that the force applied to the connection is distributed evenly across the corners, preventing the flanges from loosening or detaching.

Key Features and Advantages

The most important features of Kian Fan's TDC corners are their manufacturing precision and high strength. These components are produced with precise machinery to ensure no play occurs in the flange connections. High strength in the corners reinforces the focal point of the connection and prevents air leakage at the most sensitive points of the network.

Using these corners drastically increases installation speed; as the assembler can simply place the corner in its position and secure it with a bolt, without the need for welding or more complex operations. Resistance to corrosion and rust due to the use of galvanized material guarantees the lifespan of the connection system. Also, these corners, alongside the EPDM sealing tape, provide the necessary pressure to compress the rubber and create a complete seal.

Specialized Applications

TDC flange connection corners have vital applications in all projects that use rectangular ductwork systems with TDC connections. In large office and commercial buildings with extensive duct networks, these corners are used to connect thousands of flange points. In factories and industries, where ducts must withstand higher pressures, the strength of the corners becomes doubly important.

Also, in central HVAC systems of hospitals and laboratories where air leakage is unacceptable, the use of high-quality Kian Fan corners is essential to guarantee the performance of the TDC flange. This small but vital auxiliary component plays an important role in the integrity of the entire system.

Conclusion

The corners for TDC flanges by Kian Fan Industrial Production Group, relying on production precision and high-quality materials, guarantee strong, safe, and sealed connections. Choosing these standard auxiliary components significantly enhances the final quality of the ductwork system.