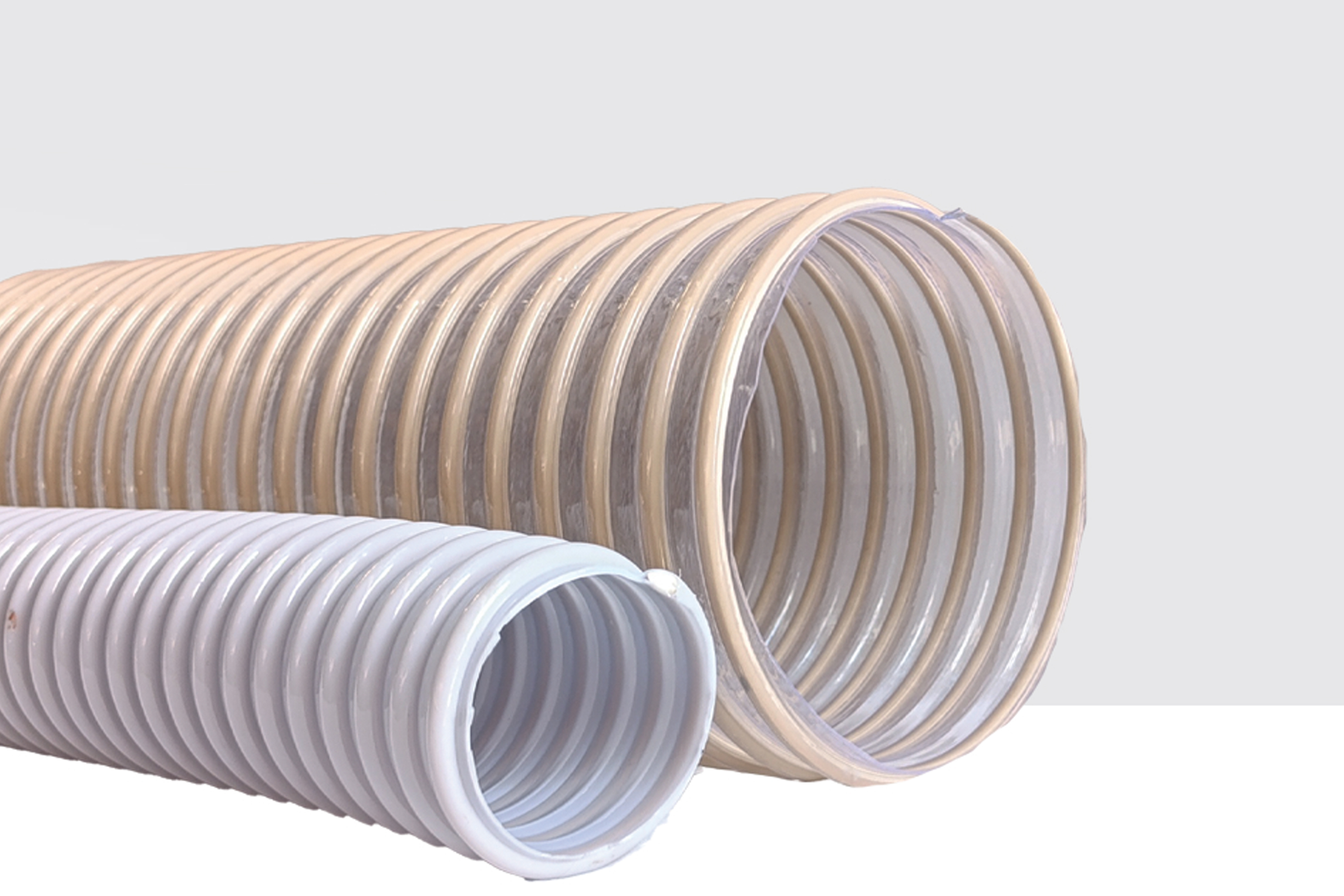

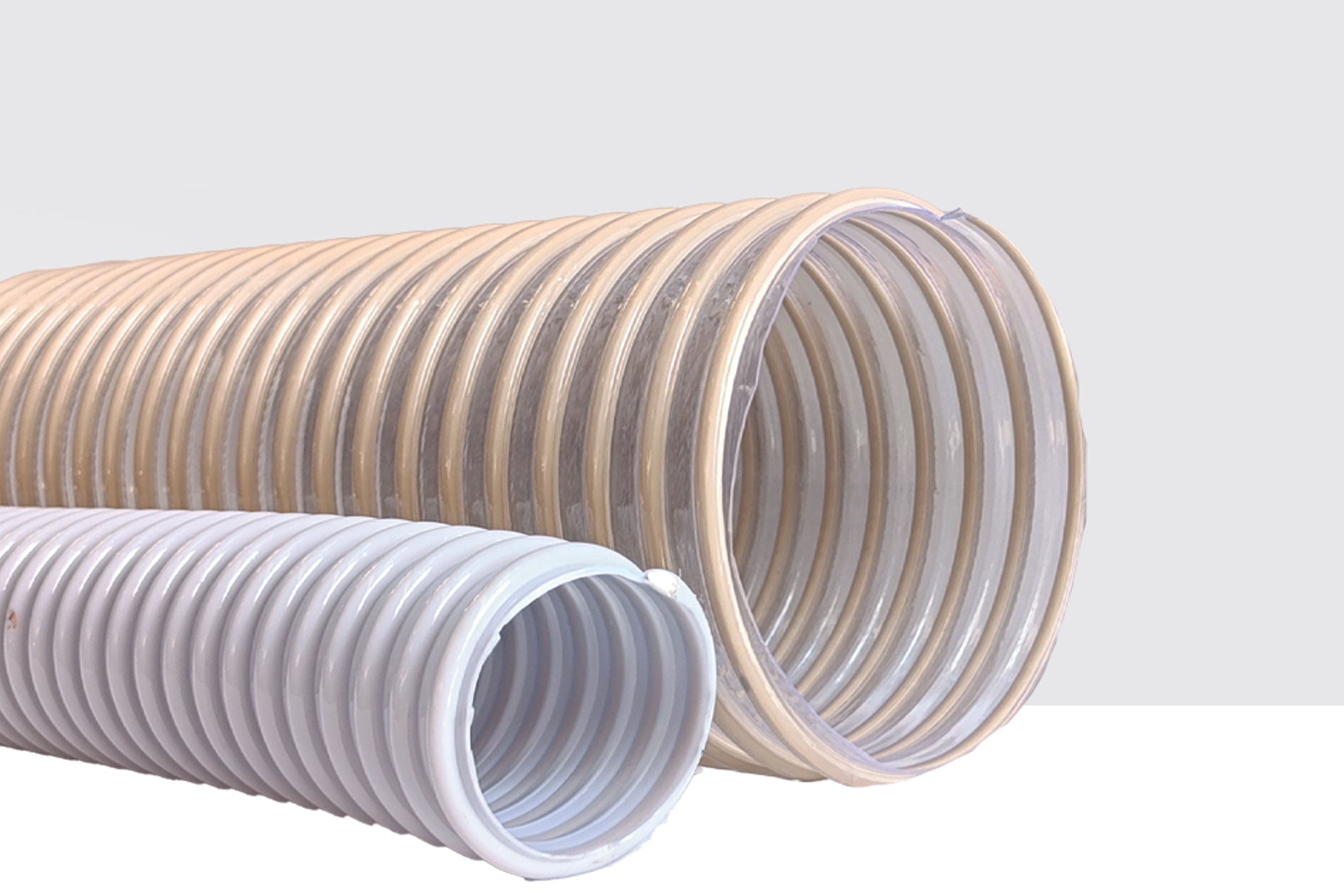

Fountain Hose (Hi-Flex)

توضیحات

The fountain hose (Hi-Flex) produced by Kian Fan Industrial Group, utilizing a novel structure of soft PVC reinforced with a PVC SOJ spiral, offers a unique combination of high flexibility and mechanical strength. This product, which can operate within a temperature range of -20 to +70 degrees Celsius (temporarily up to 80 degrees), is considered an ideal choice for suction and transfer of abrasive and granular materials due to its smooth internal surface and extraordinary resistance to abrasion and tearing. The 20-meter branch length and lightweight of this hose make it an optimal and economic choice for industrial ventilation projects, fluid transfer lines, and dust collection systems.

توضیحات تکمیلی

Introduction and Technical Structure

Fountain hoses, also known by the trade name Hi-Flex, are among the advanced products in the family of flexible hoses that Kian Fan Industrial Production Group manufactures to meet the specialized needs of the ventilation and material transfer industry. The structure of this product consists of a tube made of high-quality soft PVC that is reinforced by a resistant spiral made of PVC SOJ. This reinforcing spiral, in addition to maintaining the cylindrical shape of the hose, drastically increases its resistance against external pressures, crushing, and twisting.

This product is supplied in a diameter range of 2 to 25 centimeters and in long 20-meter branches, a feature that allows covering long paths with minimal connections and leakage. The operating temperature range of these hoses is between -20 to +70 degrees Celsius, but its robust structure allows it to withstand temperatures up to 80 degrees Celsius temporarily and for short periods. This feature makes Hi-Flex suitable for applications with temperature fluctuations.

Prominent Features and Advantages

One of the most important features of Kian Fan's fountain hose is its high resistance to tearing, which is a result of using the PVC SOJ reinforcing structure. Unlike ordinary hoses that may tear due to stretching or impact with sharp objects, Hi-Flex has high tensile strength. The smooth and uniform internal surface of this product is another advantage that reduces the friction of the airflow or materials passing through; this prevents premature wear of the channel when transferring abrasive materials such as dust and wood particles, and increases transfer efficiency.

High flexibility and light weight make the installation and transportation of this product easy and exert little pressure on supporting structures. The capability to be produced with different body and spiral thicknesses allows engineers to select a product suited to their needs based on load intensity and the type of transfer mechanism. Also, the good resistance of this product to abrasion makes it suitable for harsh working environments.

Diverse Applications

Fountain hoses (Hi-Flex) have very widespread applications in various industries. In suction and transfer systems for abrasive materials, such as furniture production lines, woodworking workshops, and stone cutting industries, these hoses show excellent performance and resist the sharpness of suspended particles.

In addition to solids, this product is also used for suction and transfer of liquids. Due to its waterproof and resistant structure, it can be used in water drainage systems or transfer of non-corrosive fluids. In commercial and industrial ventilation, Hi-Flex is considered an ideal choice for connecting ventilation devices to main ducts, especially where a flexible pipe with long length and high strength is needed. It is also used in grain and cereal transfer systems in the food and agriculture industries due to its smooth internal surface and non-absorption of materials.

Conclusion

The fountain hose (Hi-Flex) of Kian Fan Industrial Production Group, combining flexibility, strength, and high lifespan, provides an intelligent response to modern industrial needs. Using this product guarantees reduced repair and maintenance costs and increased productivity in material transfer and air ventilation systems.

Structure: Soft PVC reinforced with a spiral made of PVC SOJ

Diameter range: 2-25 cm

Branch length: 20 meters

Operating temperature range: -20 to +70 degrees Celsius (temporarily up to 80 degrees Celsius)

Features

- High resistance to tearing due to PVC reinforcing structure

- High resistance to abrasion

- Smooth internal surface

- High flexibility

- Lightweight

- Capability to be produced with different thicknesses

Application

- Suction and transfer of abrasive materials such as dust, powder, wood particles, grains, etc.

- Suction and transfer of liquids

- Commercial and industrial ventilation